Wonova

Wonova is a vision for 3D printed enclosure platform developed that provides a solution to lower the carbon footprint of the building construction industry. The platform is a complete system redesign and process reorganization for the production and installation of envelopes of all kinds. Using the concept of mono-materiality, Wonova uses as little virgin material as needed and provides maximum recyclability. In an effort to reach net carbon zero, structural efficiency and thermal performance are also optimized. The platform achieves these goals with on-site 3D printing and refabrication to reduce transport costs, on-site complexity, and post-construction waste.

Funding: Province of Noord Holland

Partner: Eckersley-O’Callaghan Engineers

Read more after the images…

Urban Oasis

Facade Renovation

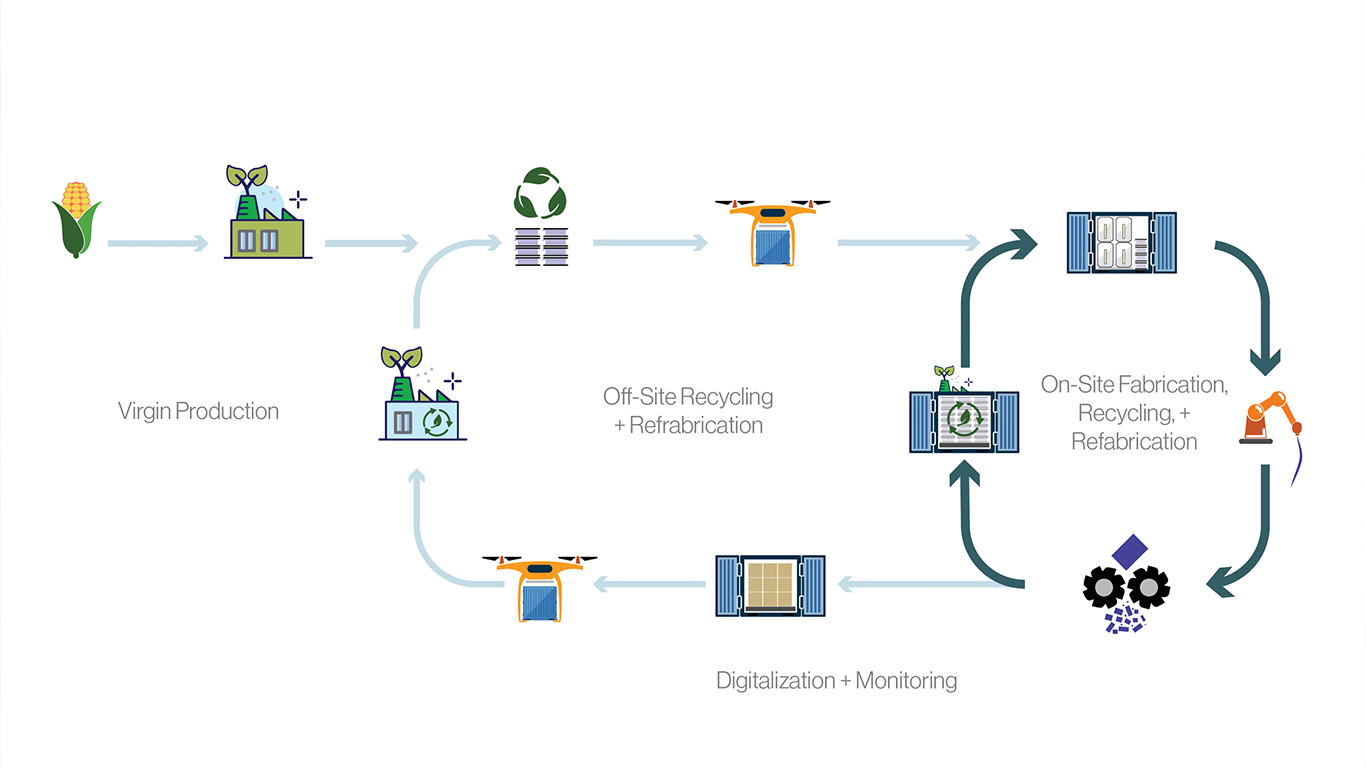

Circularity Through Refabrication

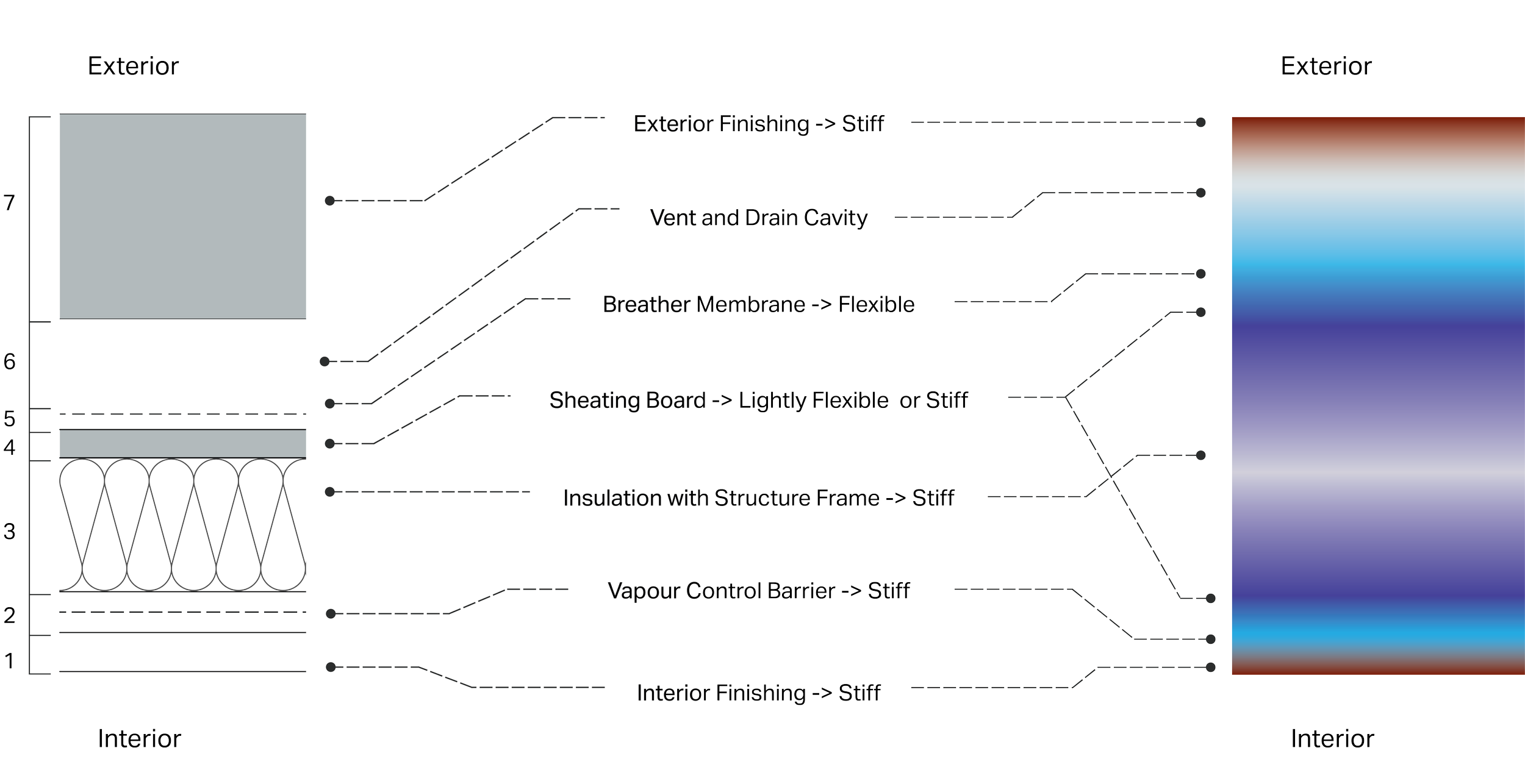

Facade Layered Components

System Build-up

System Build-up Connection

Thermal Performance

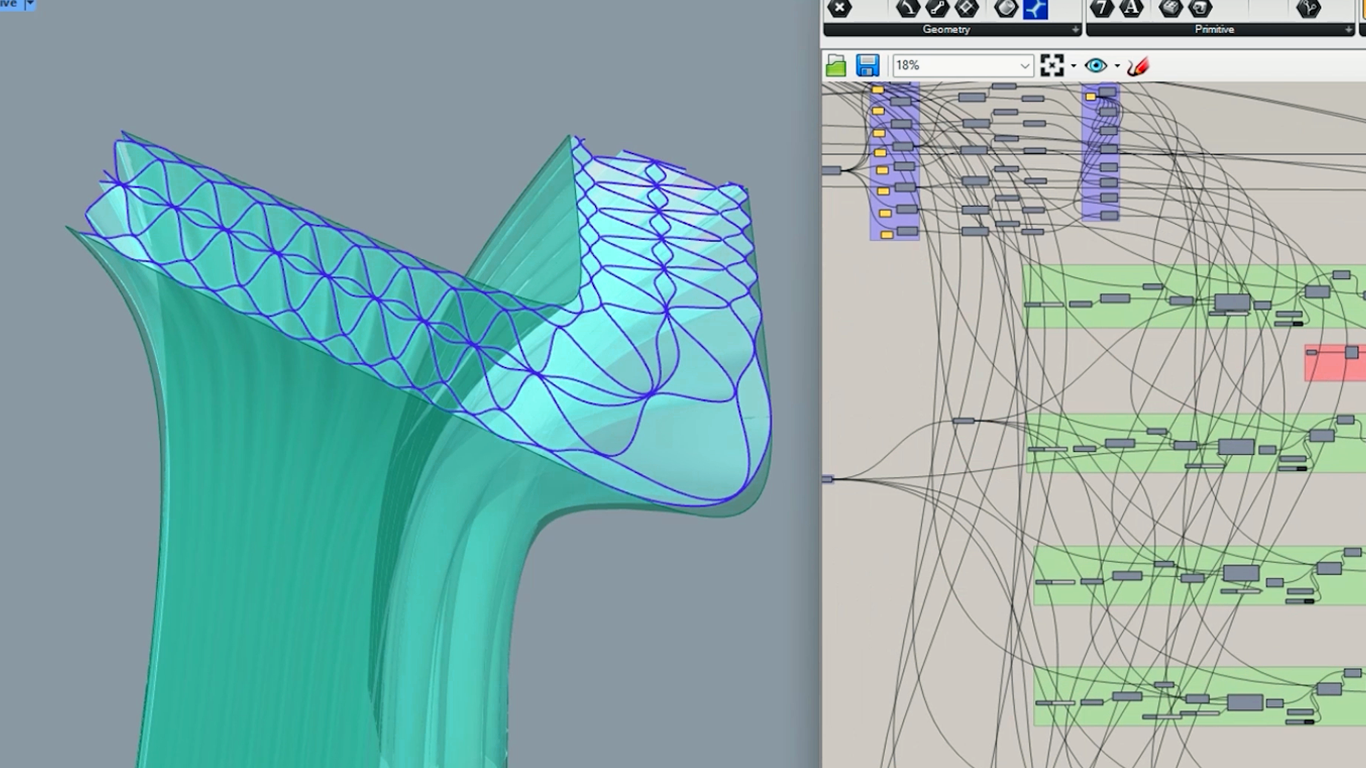

Parametric Infill

Arctic Remote Outpost

The Logo

Wonova began as a feasibility study into the possibility of scaling up the digital weaving process used for shoes and other apparel. Fairly quickly we were aware that this specific process was not feasibly scalable. Nevertheless, we were tilling fresh and fertile ground.

Using the deep knowledge of building envelopes at both Etcetera and Eckersley O’Callaghan, Wonova has developed into a more ambitious attempt to go beyond the limits of current production and installation. To this day building envelopes require multiple materials contained in several products provided by many suppliers, requiring significant manual labor for fabrication and installation. In this process is significant material and energy waste. We want to avoid the myriad packaging, transport, installation, and demolition inefficiencies that cause this waste.

The system build-up to replace the standard envelope has been carefully considered and studied computationally to meet required structural and thermal criteria, providing a base for the design of the system. The system concept provides flexibility to exceed the thermal performance of a typical opaque façade and adjust to the needs of different climates, environments, and local regulations.

While there is an intentional radicality in the platform, it builds on a combination of currently available technologies. For instance, we know that polyamide can be bio-based and recyclable to a very high percentage, which is one of the most important components of circularity, and this same polyamide can be used with robotic 3D printers. In recent years, robots have been developed to place anchors for hanging façade panels and for physically installing façade panels.

Some material and site-based production development is still required to make Wonova a reality, and we are in the process of building research and commercial partnerships for this. In the next years we must make such steps in order to repair the damage that the building industry has done to the climate.

Check out the Wonova Prototypes page elsewhere on our site.

Reach out to us if you’d like to get involved!